Last updated: March 11, 2020

Hydraulic Accumulator

In a hydraulic system, energy can transfer by means of pressure. Sometimes though it is also necessary to store hydraulic energy for a short time. Thus we use a hydraulic accumulator. As we store energy by compressing spring or inflating balloon similarly we can store energy in the accumulator in the same manner. We use pressure for storing energy in both spring and balloon. Below is some paragraph you can find the hydraulic accumulator working principle.

A hydraulic accumulator is used to store hydraulic energy by using the back pressure of gas, spring or weight. Hence we can categorize the accumulator in the following.

- Gas pre-charged accumulator

- Spring-loaded accumulator.

- weight load accumulator.

1. Gas pre-charged hydraulic accumulator working principle

A gas pre-charged accumulator is charged with a non-toxic, non-reactive gas such as nitrogen. When the system’s hydraulic pressure increases above the accumulator charging pressure the gas begins to compress. Hydraulic oil starts to flow in the accumulator container. The gas and oil separate by means of some membrane. That happens until the gas pressure matches the hydraulic pressure. Hydraulic kinetic energy is now stored in potential energy in gas pressure. When the pressure in the hydraulic circuit declines, the same thing happens in the hydraulic accumulator. The gas expands again. The stored energy now converts back into motion. It pushes the hydraulic fluid back into the circuit until the gas pressure has dropped to the value of the hydraulic pressure or original pre-charge pressure whichever is more. In fact, the charging-discharging accumulator is very fast and happens at the same time with system pressure.

Now, we will see how accumulator can help us in hydraulic system in more details.

Let’s see how hydraulic accumulator can help in a hydraulic system

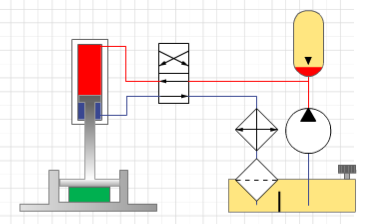

Let us consider an example, a hydraulic press is tasked with compressing a workpiece. It needs a lot of force (know why) to do that, but only at a low speed. It means we need high pressure with a low flow rate pump. The recirculation after pressing means piston for retraction does not need much force, but it needs to go quickly, which means low pressure and high flow rate pump. To full fill both condition we need to adjust the pump which is pretty expensive.

But, the hydraulic accumulator gives the solution. We can use a pump having high pressure and a low flow rate with the addition of accumulator to the delivery of the pump.

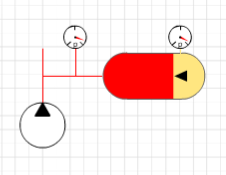

As shown in figure 4 accumulator is installed between the pump and direction control valve. The pump’s flow rate is enough for pressing at low speed. The high pressure during pressing compresses the gas in the hydraulic accumulator and it charges itself with liquid. As soon as the retraction of piston starts due to less load restriction pressure will drop in the circuit. Therefore, the gas in the hydraulic accumulator expands pushes out the liquid and increases the flow rate. The press can, therefore, return faster than with just the pump’s flow rate.

Types of the pre-charged gas accumulator.

- Bladder type

- Diaphragm type

- Piston type

The use of these various accumulators depends on the pressure and volume required in the system. Bladder and diaphragm type accumulator is used for moderate pressure and less volume (0.5 to 500 liters). But its response time is quick. On the other hand, the piston-type accumulator is used for high pressure and large volume (more than 500 liters). But it has low response time because of piston large mass. Lastly, the pre-charged gas accumulator should mount in the specified position as per design for better results.

2. Spring-loaded hydraulic accumulator working principle

In the spring-loaded hydraulic accumulator, there is a spring along with container & movable piston. A spring-loaded accumulator can mount in any position. However, the spring force is not easy to adjust. These springs create the required pressure on the hydraulic piston to pump out fluid. The amount of pumping depends upon the compression rate of the spring. The main advantage of this type of hydraulic accumulators is that they are comparatively small in size, have a low weight and are easy to assemble in the hydraulic system and at the same time cost-effective. They can be used as mobile hydraulic accumulators due to their lightweight. Because of limitations on spring sizes, the use of this accumulator is impractical where a large volume of fluid is required.

3. Weight loaded hydraulic accumulator working principle

The weight loaded type was the first used but is much larger and heavier for its capacity than modern piston and bladder types. On the other hand, it is the only type of accumulator where the pressure is constant, whether the chamber is full or nearly empty (you can know here why). It is heavy & bulky, making the use limited. For example, it is used in heavy presses where constant pressure is required.

Example: Accumulator use for damping in the automobile.

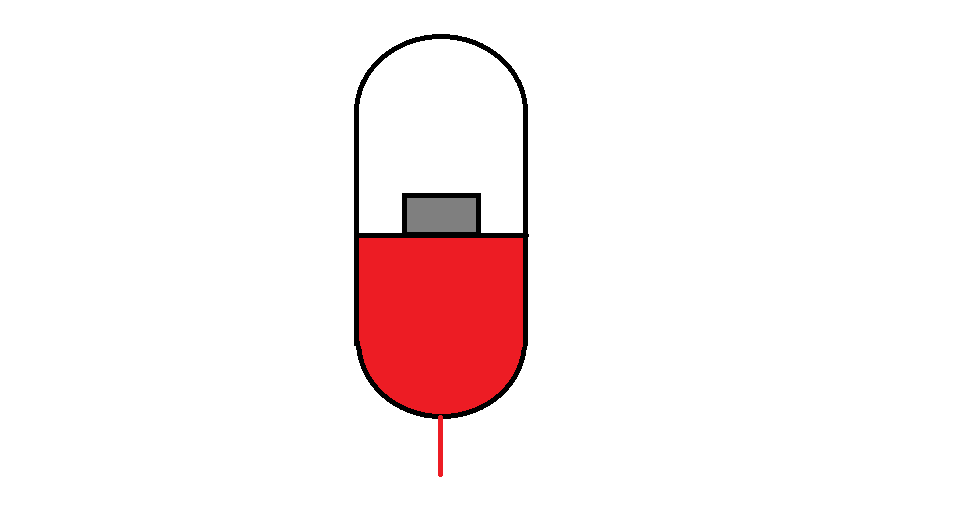

For damping of undesirable pressure spikes and fluctuation, we can use an accumulator. For example, hydro-pneumatic shock absorber in vehicles as shown in figure 7. It basically consists of a hydraulic cylinder and a gas pre-charged accumulator. If bumps in the road push the wheel upwards, the pressure in the hydraulic fluid increases abruptly. It is pushed into the hydraulic accumulator and compresses the gas present there. As a result, the gas acts as a spring. The shock’s pressure and motion are absorbed and only transmitted to the vehicle in dampened form.

As the wheel’s pressure on the hydraulic fluid attenuates after the shock, the gas in the hydraulic accumulator expands again due to the attenuated backpressure and pushes the liquid back into the cylinder.

The above example is also applicable in damping in the hydraulic system. When the hydraulic direction control valve changes position rapidly then accumulator comes into play and absorbs the sudden pressure fluctuation.

Maintenance of Accumulator

Hydraulic pre-charged does not require much maintenance but gas pressure is to be regularly checked.

For example. In a piston-type accumulator, if the charging pressure is too high, the hydraulic fluid will be completely pushed out of the accumulator at minimum operating pressure. The piston strikes the hydraulic connection and can be damaged.

The opposite happens when there is too little charging pressure. The piston is pushed completely upward against the gas valve at maximum operating pressure, and can also be damaged.

Similarly, in bladder and diaphragm type the separating membrane can be damaged due to incorrect charging pressure.

On the other hand, due to incorrect gas-charged, the usable volume of hydraulic fluid needed for the system changed. These results alter the behavior of the system and can damage other hydraulic components.

The procedure of gas charging

- Firstly, the hydraulic system must not be pressurized

- The charging equipment should directly connect to the accumulator gas valve.

- There must an integrated gauge in the charging kit which will the show prevailing gas pressure of the accumulator.

- To charge, connect a commercially available gas cylinder to the equipment using a flexible hose.

- There should be two control valves for controlling the amount of gas in an accumulator. One will control the gas cylinder and one will control accumulator gas.

- After connecting the charging kit, the first thing is to open the check nut of the accumulator. Then open cylinder control valve little and open the accumulator gas control valve. After that check for leakage and then close completely.

- If there is no leakage the then completely open the cylinder gas control valve. And by accumulator gas control valve charge the accumulator with the required pressure. Then tight the check nut. Do not over tight and damage the check nut.

- Then First close the cylinder control valve and then remove the charging kit from the accumulator gas valve.

Safety regarding accumulator

- Do not weld the accumulator. It may damage the accumulator and cause serious injury.

- Do not drill for fastening with bolts.

- Only secure the accumulator instructed by manual like secure with strap in instructed position.

- Before maintenance release the accumulator pressure securely. It may store pressure energy even in stop condition and cause serious injury.

Hope you enjoyed this article. See you in next article. Till then bye bye.